Precision in the cleanroom

Innovative solutions for precise and safe processes in sensitive environments

Stable

processes

State-of-the-art automation technology increases productivity and ensures safety in your cleanroom.

Flexible

integration

Customized systems for your production requirements.

Smooth

processes

Automated processes increase productivity and reduce sources of error.

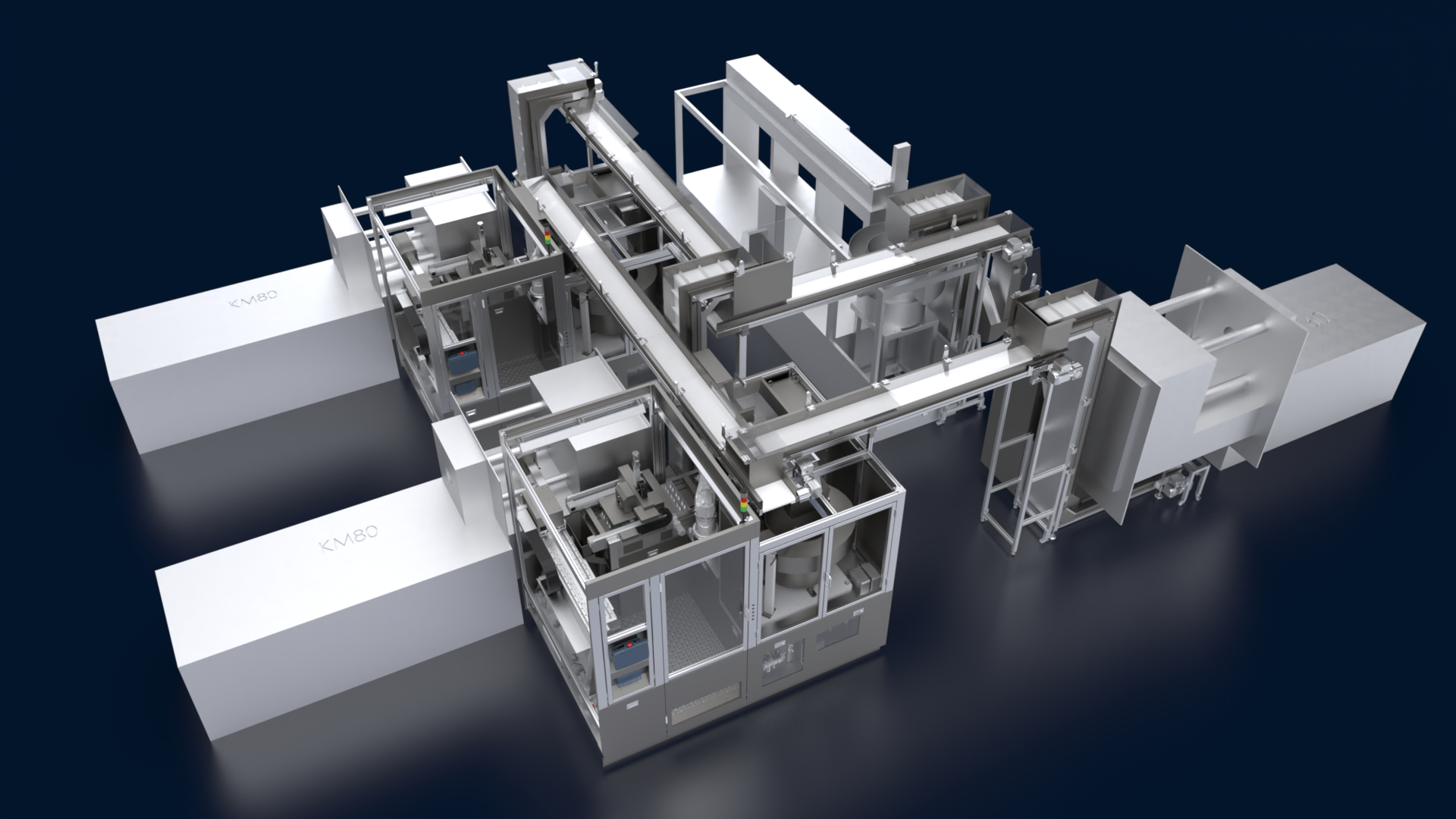

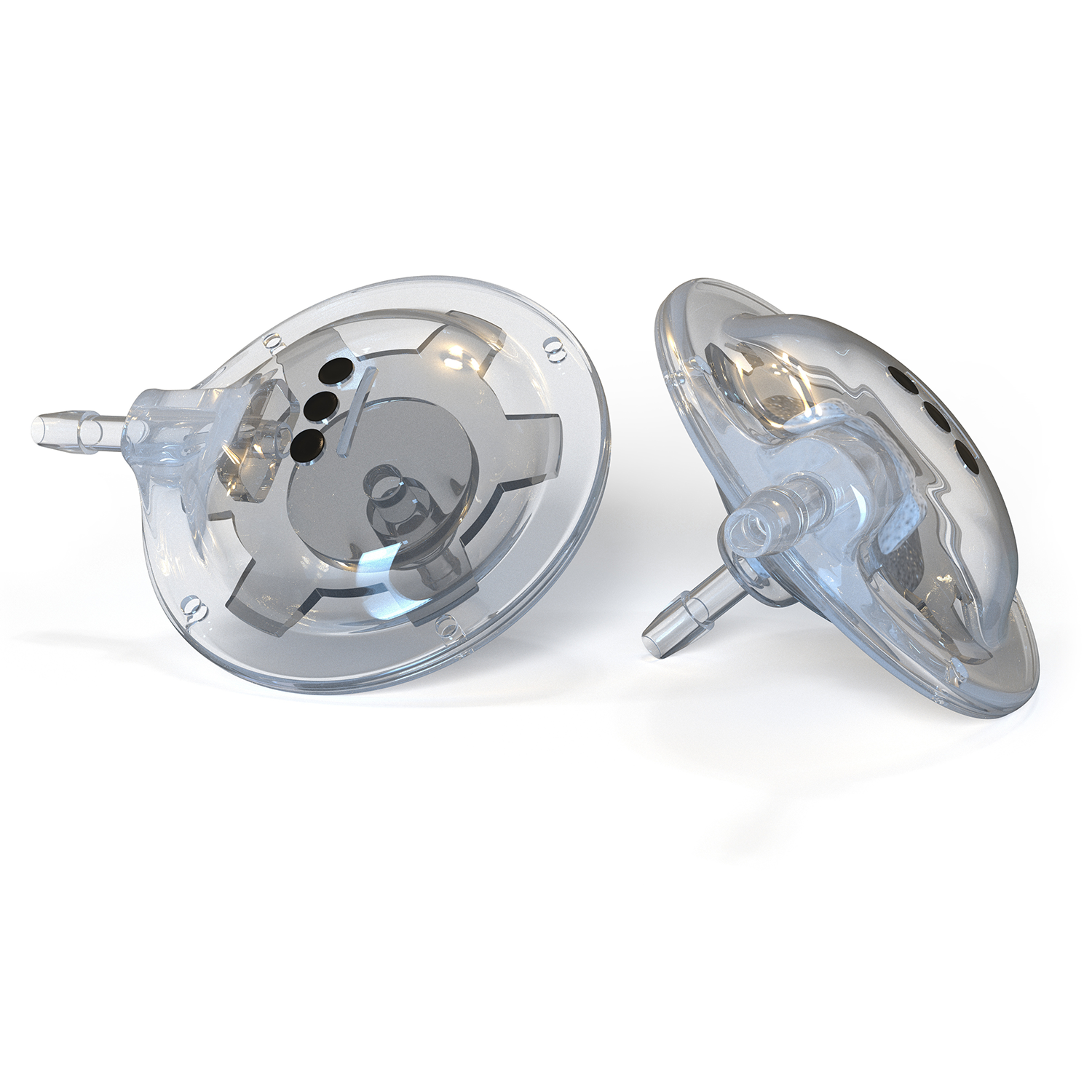

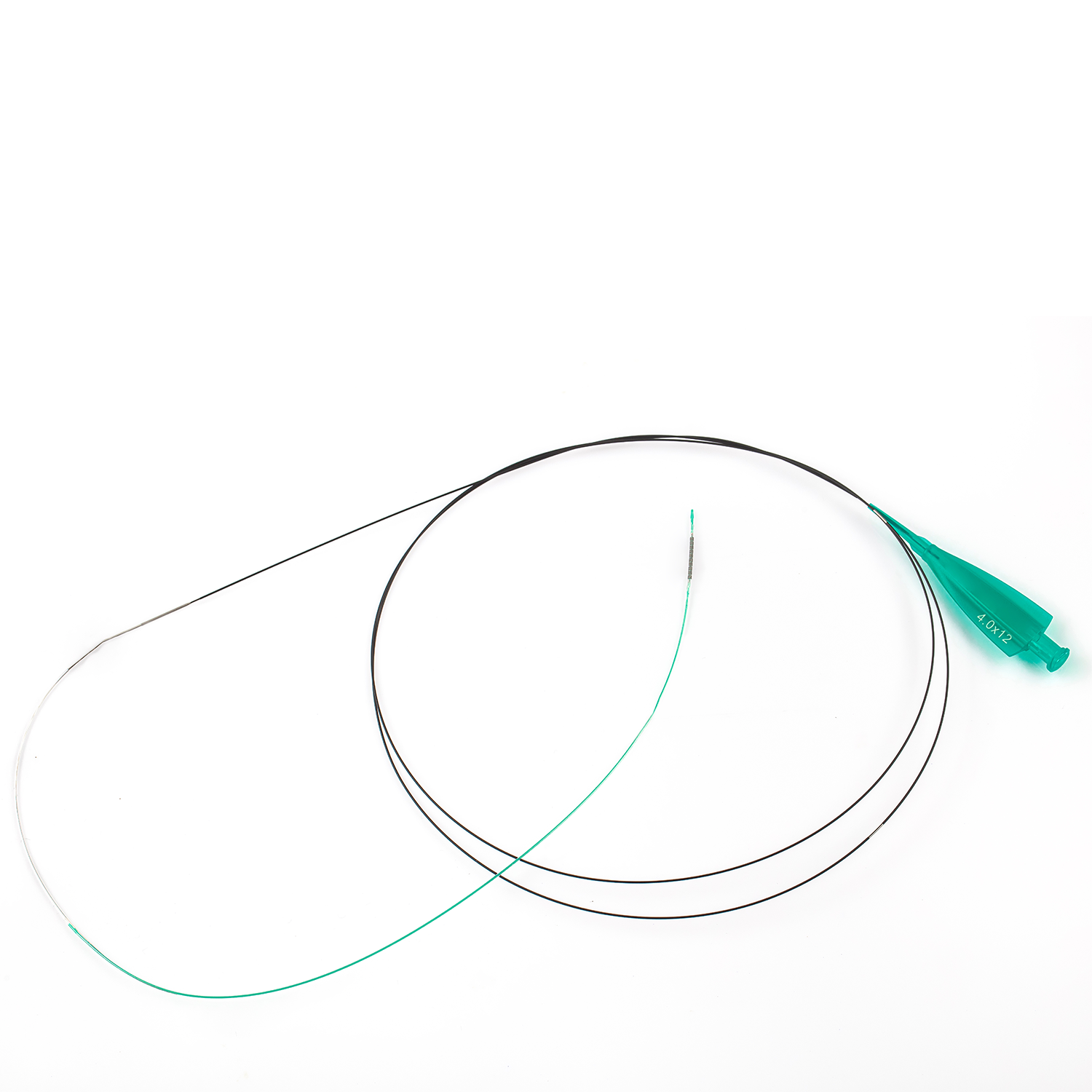

Series accuracy: automation for medical technology

We support you as a reliable expert when it comes to tailor-made systems for cleanroom applications. With comprehensive expertise and many years of experience, we meet the highest demands of cleanroom technology. Our complete turnkey solutions are tailored to your specific requirements and offer you maximum safety and functionality.

Cleanrooms and demanding cleanliness specifications require special care in planning, implementation and operation. We implement projects in the medical technology, cosmetics and white goods sectors, placing particular emphasis on quality, flexibility and an appealing design. Each system is designed so that it fits perfectly into your processes and reliably meets the required cleanliness standards.

Our stainless steel assembly and testing systems are specially designed for use in cleanrooms. They ensure stable processes, support compliance with the strictest hygiene requirements and enable efficient production. This means you benefit from durable, low-maintenance systems that make your production safe and economical.